Introduction to PPR Fittings and Pipes

PPR (Polypropylene Random Copolymer) fittings and pipes are widely used in modern plumbing systems. These materials are lightweight, durable, and resistant to corrosion, making them a popular choice for both residential and commercial applications. PPR pipes are typically used for water supply, heating, and cooling systems. The fittings are designed to connect and secure pipes, ensuring leak-proof, efficient fluid transport. Together, PPR pipes and fittings offer a versatile, cost-effective solution for a variety of piping needs. Their non-toxic and eco-friendly properties make them safe for drinking water applications. PPR pipes also resist scaling and bacterial growth, ensuring clean water flow. The smooth internal surface reduces pressure loss, improving system efficiency and longevity.

Characteristics of PPR Pipes

PPR pipes are made from a high-quality thermoplastic material known for its strength and durability. One of the key advantages of PPR pipes is their resistance to chemical reactions and corrosion, unlike metal pipes that can rust over time. They can withstand high temperatures, making them suitable for hot water systems. Additionally, PPR pipes offer excellent insulation, reducing heat loss in heating systems. These pipes are lightweight and easy to handle, which simplifies the installation process. Their long lifespan and low maintenance requirements make them a reliable choice for piping systems. PPR pipes are available in various pressure ratings, ensuring compatibility with different applications. Their soundproofing properties help reduce noise in plumbing networks, enhancing comfort in residential and commercial buildings.

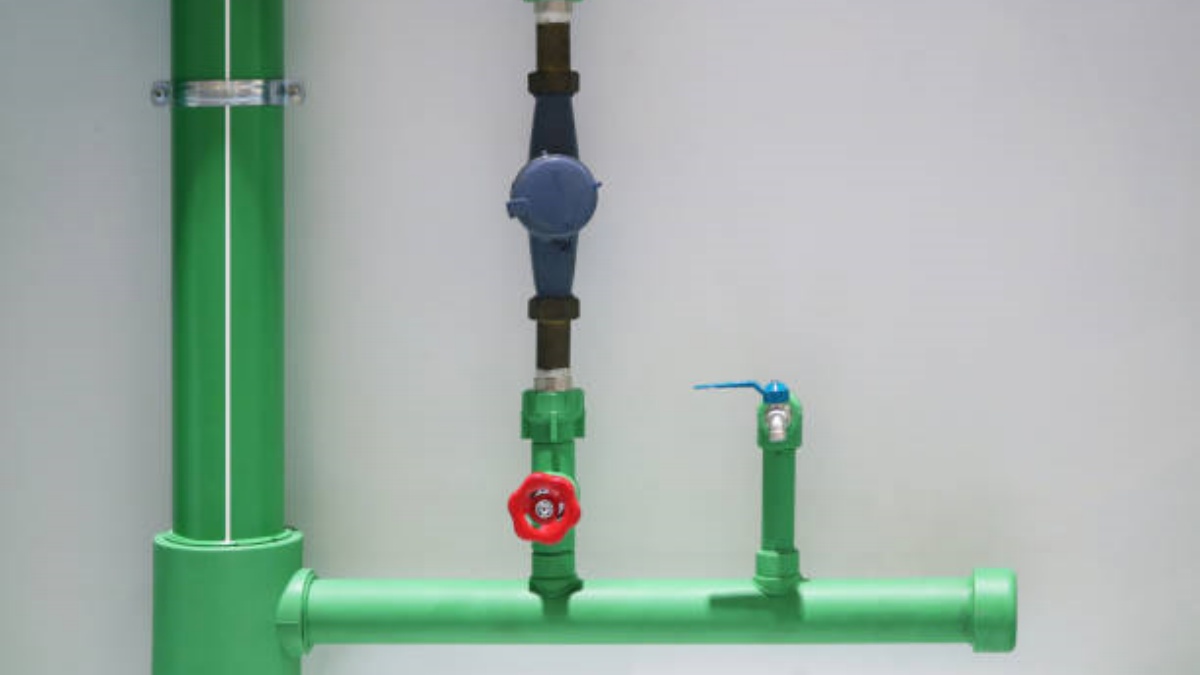

Types of PPR Fittings

PPR fittings come in a variety of shapes and sizes, designed to connect different sections of PPR pipes. Common fittings include elbows, tees, reducers, couplings, and end caps. These fittings ensure a secure and leak-proof connection between pipes. PPR fittings can be fused to pipes using heat fusion techniques, creating a strong bond that is resistant to pressure and temperature changes. This process results in smooth internal surfaces, which helps prevent blockages and improve water flow. The versatility of PPR fittings makes them suitable for a wide range of plumbing applications, from simple home installations to complex industrial systems. Other specialized fittings, such as ball valves and unions, enhance the adaptability of PPR piping. Various connection methods, including electrofusion and socket fusion, provide additional installation options.

Advantages of PPR Fittings and Pipes

PPR fittings and pipes offer numerous advantages compared to traditional materials like copper and PVC. They are lightweight and easy to handle, reducing transportation and installation costs. The fusion welding process used to connect PPR pipes and fittings ensures a uniform joint that is stronger than threaded connections, preventing leaks. Additionally, PPR pipes are resistant to scale build-up, which helps maintain smooth water flow and prolongs the system’s lifespan. They are also highly resistant to UV radiation, making them ideal for both indoor and outdoor applications. PPR systems also have lower thermal conductivity, which helps retain the temperature of hot water in pipes. Their flexibility reduces the risk of cracking under extreme conditions. Furthermore, PPR pipes are cost-effective due to their long lifespan and minimal repair requirements.

Applications of PPR Pipes and Fittings

PPR pipes and fittings are used in a wide range of applications, including water distribution systems, heating and cooling systems, and industrial piping. In residential plumbing, PPR pipes are commonly used for hot and cold water supply. They are also ideal for underfloor heating systems due to their thermal insulation properties. In commercial and industrial settings, PPR pipes can be used for transporting chemicals, gases, and liquids. Their versatility extends to agricultural applications, where they are used in irrigation systems. The durability and resistance to corrosion make PPR pipes and fittings a preferred choice in environments where metal pipes might fail over time. Hospitals and laboratories also use PPR pipes due to their hygienic properties. Swimming pools and spa systems benefit from PPR’s resistance to chlorine and harsh chemicals.

nectarplus International Standards

nectarplus‘s products comply with a wide range of international standards, ensuring high quality and reliability. These standards include ISO 15874, which specifies requirements for polypropylene piping systems, and EN 15874, the European equivalent for hot and cold water installations. Additionally, nectarplus products meet ASTM F2389, the American standard for pressure-rated polypropylene pipes. They also adhere to DIN 8077/8078, the German standards for PP pipes and fittings, and GB/T 18742, the Chinese national standard for polypropylene piping systems. Furthermore, nectarplus complies with NBR 15884, the Brazilian standard for plastic piping systems. This multi-standard compliance ensures nectarplus products are suitable for global applications, offering durability, safety, and performance. By meeting these strict quality requirements, nectarplus guarantees long-lasting and efficient piping solutions.

Contact

nectarplus is a professional manufacturer with 30 years of experience, dedicated to producing high-quality plastic pipes, fittings, and valves. Our products include brass valves, PPR valves, as well as various pipes and fittings to meet different customer needs. Whether you need plumbing and drainage pipes or valve products, nectarplus can provide a diverse range of high-quality, cost-effective products to support your projects. Below is our contact information.

We will reply to your email or fax within 24 hours.

You can call us at any time if there is any question about our products.

Pls Mailto: [email protected]