Introduction to PEX

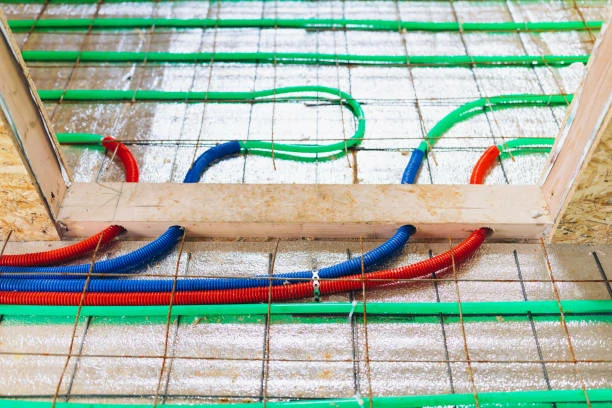

Cross-linked polyethylene, or PEX, has become a popular material in modern plumbing systems. It is a type of plastic tubing known for its flexibility, durability, and resistance to various environmental factors such as temperature changes and corrosion. PEX is commonly used for residential and commercial water supply systems, radiant floor heating, and even snow melting systems. The main advantage of PEX over traditional materials like copper or PVC is its ability to be installed easily without the need for many fittings, which reduces the risk of leaks. To suit different installation needs, PEX comes in three primary types: PEX-A, PEX-B, and PEX-C, each with its unique features and applications.

Types of PEX Tubing

There are three primary types of PEX tubing: PEX-A, PEX-B, and PEX-C. Each one is produced using a different method, resulting in variations in flexibility, durability, and cost. PEX-A, produced through the peroxide method, is the most flexible type of PEX. This flexibility makes it ideal for bending around corners without needing fittings, which reduces the chance of leaks. PEX-A is also resistant to cracking under stress and is highly durable at both high and low temperatures. PEX-B is produced using the silane method, which results in a less flexible but more rigid pipe. It is more resistant to cold cracking and has better resistance to chlorinated water, making it suitable for colder climates. PEX-C, manufactured using the electron beam method, is the least flexible of the three but offers high strength and resistance to higher temperatures and pressure. It is commonly used in commercial and industrial applications.

Advantages of PEX-A, B, and C

Each type of PEX has specific advantages that make it suited to different applications. PEX-A is the most flexible and easy to work with, making it an excellent choice for residential plumbing and DIY projects. Its flexibility allows it to bend around corners, reducing the need for elbows and fittings. This can save time and reduce installation costs. Additionally, PEX-A is highly resistant to kinking, making it ideal for use in tight spaces. PEX-B is more rigid but offers increased resistance to freezing and cracking in low temperatures. This makes it a solid option for plumbing in colder regions. It’s also more cost-effective compared to PEX-A, making it popular for large-scale residential installations. PEX-C, with its superior pressure and temperature resistance, is often the go-to choice for commercial or industrial plumbing systems, where strength and durability are crucial. While PEX-C is not as flexible, its higher resistance to heat and pressure compensates for this limitation in demanding applications.

Ways to Connect PEX Tubing

Connecting PEX tubing requires specialized fittings and tools. There are three main methods for connecting PEX pipes: crimping, clamping, and push-fit. The crimping method involves using a copper crimp ring and a crimping tool to secure the fitting onto the tubing. This is the most common and cost-effective connection method, especially for residential installations. The crimped connection forms a secure bond, but it requires careful attention to avoid over-tightening or under-tightening, which can cause leaks. Clamping is similar to crimping but uses stainless steel clamps and a clamping tool. Clamps are more flexible than crimp rings and offer a stronger connection, particularly in high-pressure systems. This method is widely used in both residential and commercial plumbing. Push-fit connectors are the easiest to use, requiring no tools or special skills. These connectors have built-in mechanisms that lock the pipe into place when inserted into the fitting. Push-fit connectors are ideal for DIY plumbing, as they eliminate the need for crimping or clamping tools, making installation quick and straightforward.

Choosing the Right PEX and Connection Method

The choice of PEX type and connection method depends on various factors, including budget, installation complexity, and the specific requirements of the plumbing system. For DIY homeowners, PEX-A with push-fit connectors is a great choice. The flexibility of PEX-A and the simplicity of push-fit connectors make installation easy and user-friendly. If cost is a major concern, PEX-B with crimp or clamp fittings is a good option, as it offers a more affordable price without sacrificing performance. For professional installers or those working on commercial projects, PEX-C with clamp or crimp fittings may be the best option. PEX-C’s resistance to higher pressures and temperatures makes it ideal for larger systems where durability is essential. When selecting PEX and the appropriate connection method, always consider factors like local climate conditions, the size of the plumbing system, and the specific demands of the project to ensure the best results.

Global Standards for PEX Pipes

PEX pipes adhere to various international standards to ensure their safety, reliability, and performance in different applications. Key standards include ISO 15875, GB/T 18992, and DIN 16892, each catering to specific regions and requirements. ISO 15875 covers hot and cold water systems, defining criteria for material properties and performance under varying temperatures and pressures. GB/T 18992 focuses on specifications for China, ensuring PEX pipes meet the country’s unique environmental and regulatory standards. DIN 16892 is specific to Germany, ensuring PEX pipes meet stringent performance and safety criteria for domestic water supply and heating. ASTM F877 and ASTM F2788 apply in the U.S., outlining requirements for PEX pipes used in water distribution and hydronic heating systems. In the UK, BS 7291 and BS EN ISO 15875 regulate PEX pipe specifications for various plumbing and heating applications. Lastly, CSA B137 covers Canadian standards, emphasizing performance in both potable water and heating systems. These global standards ensure that PEX pipes are durable, safe, and suitable for diverse plumbing needs across different countries.

Contact

nectarplus is a professional manufacturer with 30 years of experience, dedicated to producing high-quality plastic pipes, fittings, and valves. Our products include brass valves, PPR valves, as well as various pipes and fittings to meet different customer needs. Whether you need plumbing and drainage pipes or valve products. nectarplus can provide a diverse range of high-quality, cost-effective products to support your projects. Below is our contact information.

Nous répondrons à votre e-mail ou fax dans les 24 heures.

Vous pouvez nous appeler à tout moment si vous avez des questions sur notre production.

Veuillez envoyer un mail à : [email protected]