Axé sur les personnes, bons produits, innovation continue, service honnête

About Us

Nectar Plus

Since its establishment in 1993, NectarPlus has been committed to the plastic pipe industry for more than 20 years. It has now developed into a collection of PP-R water supply, PVC drainage, PVC electrical pipes, PE water supply and drainage pipes, PE-RT/PE-X heating pipes, aluminum-plastic series and other civil pipes, HDPE municipal sewage, and home improvement intelligent pipe supporting equipment A large-scale comprehensive new building materials enterprise integrating products.

Our location

Location: Germany

Total area: 6.200 sm

Production area: 3.200 sm

Storage area: 3.000 sm

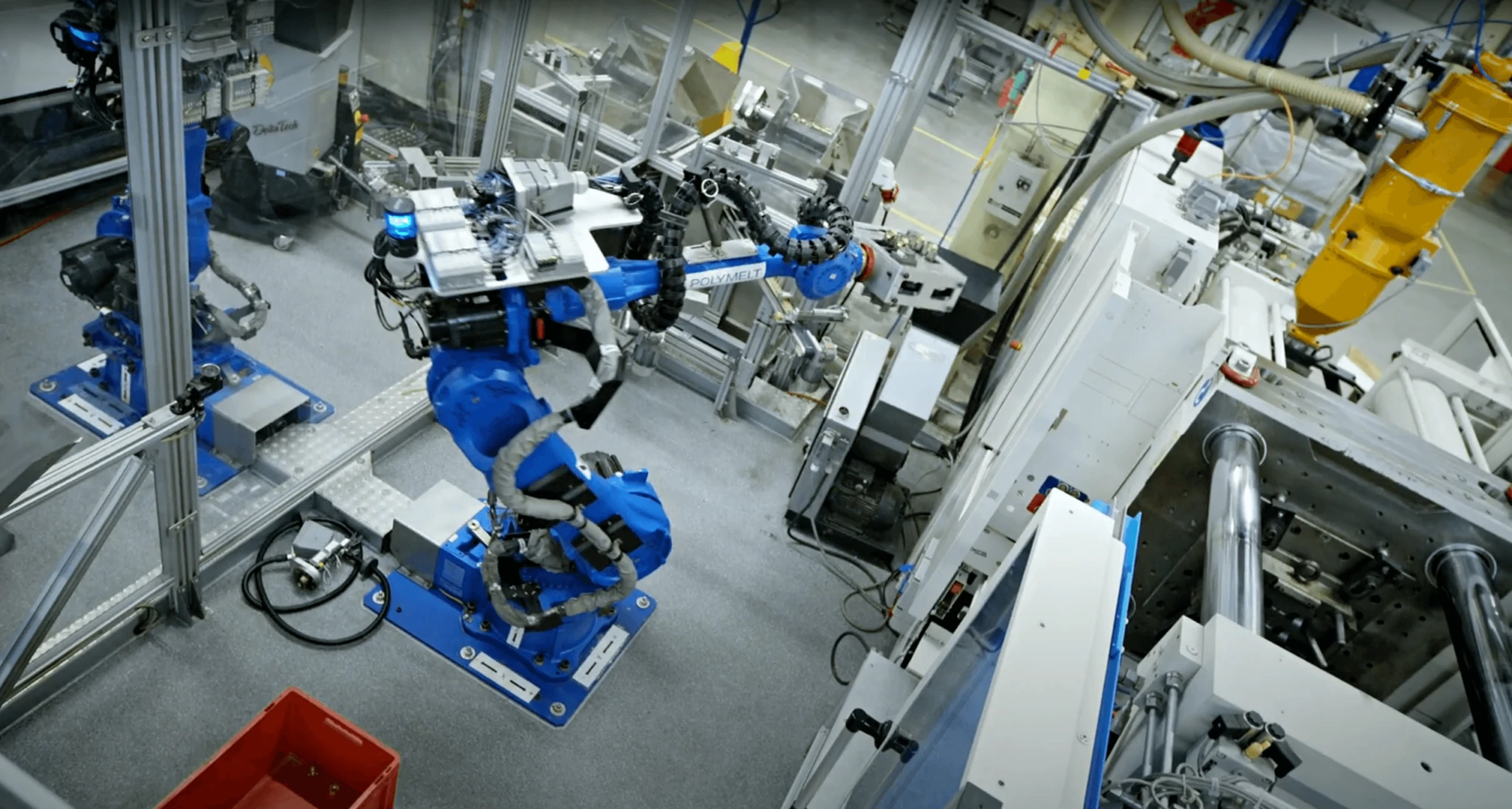

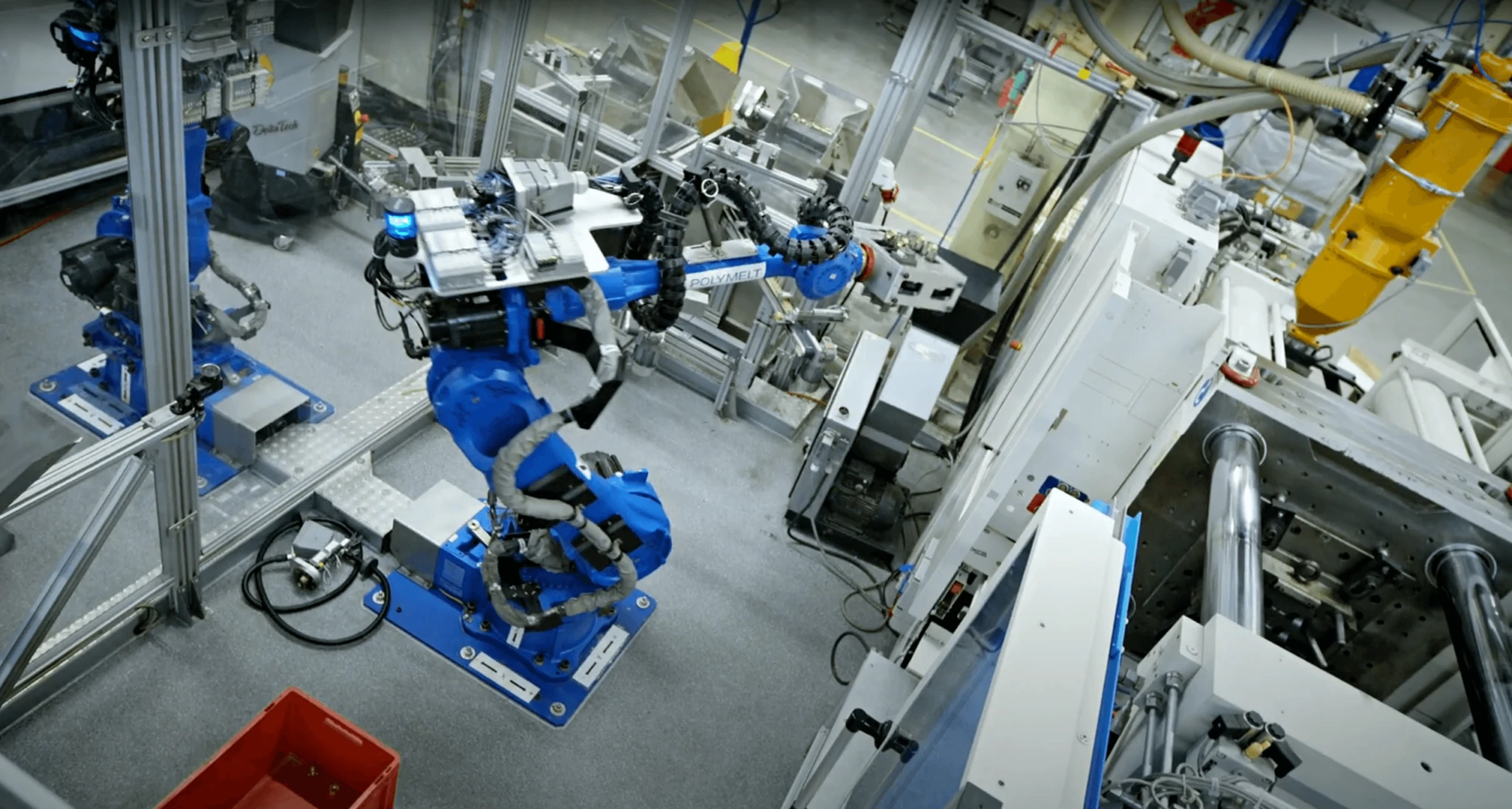

Pipe & fitting manufacturing pipes/pipe extrusion

7 Extrusion lines (Krauss Maffei) for single-layer or multilayer (up to five layers) pipes from 20 to 250 mm. Maximum total output of approx. 30 tonnes/day.

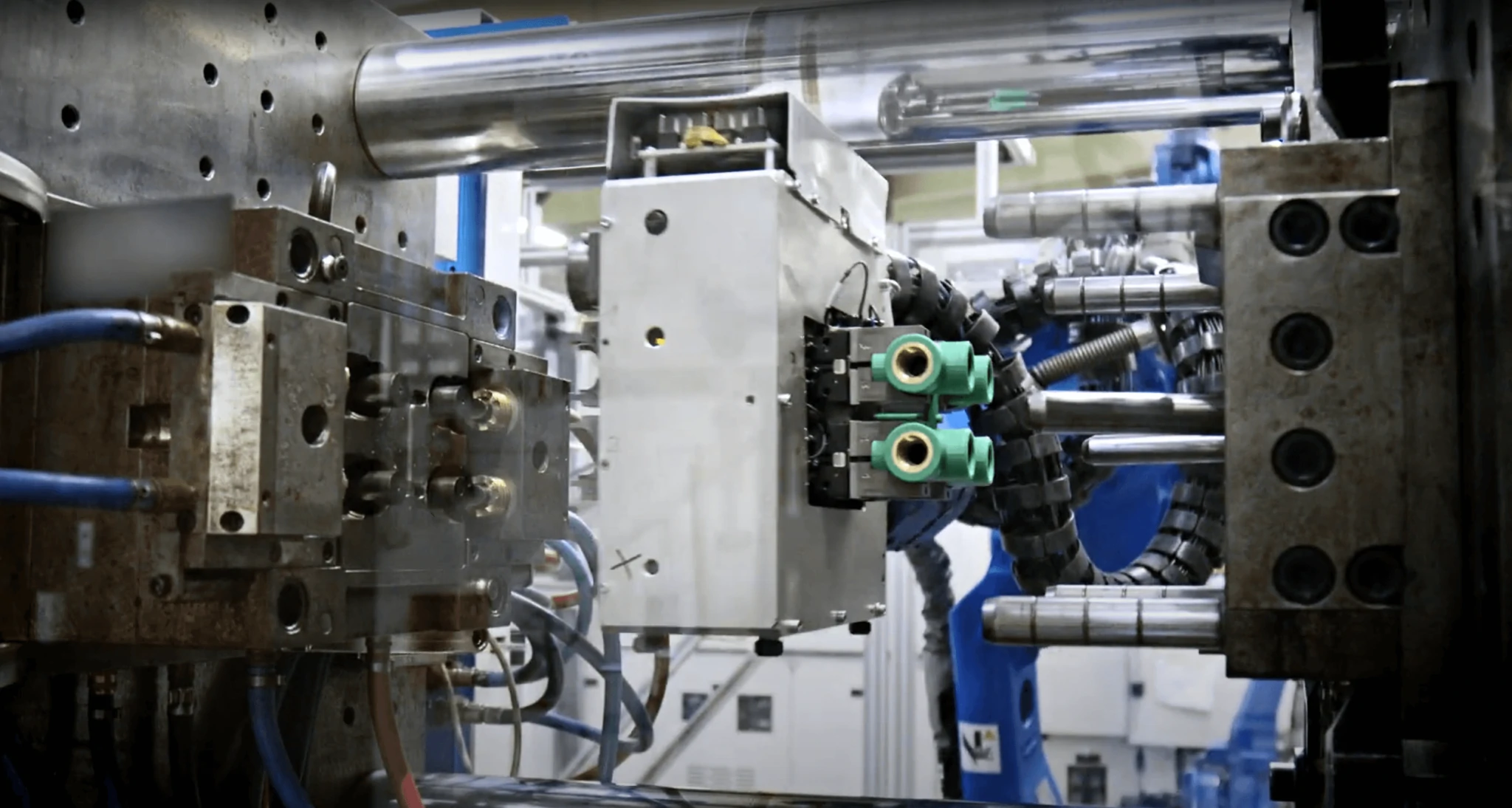

Pipe & fitting manufacturing fittings/injection moulding

23 injection moulding machines. Clamping force 850 to 10,800 kN. The shot weight varies from 120 to 1,100 tonnes for almost all common thermoplastics. Maximum total output of 6 tonnes/day

Expertise & philosophy

Over 70 years of experience in polypropylene processing.

Continuous technology breakthroughs in product development.

Proven high quality standards.

Efficient optimisation of production processes.

Commitment to environmentally friendly manufacturing processes and sustainable materials.

Successful expansion in global markets with an established network.

Long-term customer satisfaction and long-term partnerships.

Quality assurance

We monitor all production processes from start to finish with our continuous quality assurance.

This includes

Careful selection and inspection of raw materials

Continuous monitoring and control of the production processes

Regular checking of tolerances

Tests: Mechanical stress, pressure tests, temperature tests

Long-term tests- Monitoring of surface quality

Conformity to standards: Compliance with international standards and regulations

Implementation of traceability mechanisms

International certification and accreditations

- Qualitymanagement-System ISO 9001:2015

- DVGW

- SKZ

- KTW-Guideline Hygiene Institute

- ÖVGW

- WRAS

- NSF

Why choose us

01.

Advanced production equipment

We have 30 extruders, 60 injection molding machines and 200 CNC machines, and the quality control equipment includes “hydrostatic pressure equipment, melt measurement equipment, salt spray tester, torque measurement equipment, tensile equipment, pressure tester” and so on

02.

Professional R&D team

We have a strong and professional team, including 600 employees, and a R&D and technical backbone team of more than 50 people, including “50 R&D employees and 27 QC employees.” Meet your product needs

03.

Strong production capacity

We have more than 30 production lines and more than 600 manufacturing employees. Our annual output value is as high as 200 million. Our strong production capacity is worthy of your trust.

04.

Advanced corporate philosophy

The company, as always, adheres to the development concept of “only a starting point, no end”, and always adheres to the spirit of excellence “people-oriented, good products, continuous innovation, and honest service”

strategic partners

Pay close attention to international technological developments and industry frontiers, and timely integrate global resources to create value. Integrate global resources to create value.